Overview:

Single fluidized bed generally requires a larger air volume, energy-intensive, equipment shape longer. To address these shortcomings, our company has developed a multi-layer vibration dryer, a spiral surface, the round, three kinds of linear structure, can be selected according to different materials, especially for large output, low when the product moisture content of materials and crystal particles drying process. Equipment from the hot air system, multi-layer drying host, vibration motor, vibration system, feeding system, dust removal system and control system composed of seven parts, with the drying bed area is large, dry, high efficiency, small footprint, the investment characteristics of the province, line GMP Requirement for the replacement of ordinary fluidized bed of innovative products.

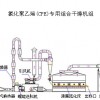

Dry material from the top of the feeding device into the opening, the vibration and its own gravity, the material moving from the bottom, and finally from the bottom of the discharge port. Into the hot air from the bottom, flows up through the perforated bed, while the material with the bed full of heat and mass transfer, and finally through the top of the humidity and discharge port, part of the small separation of silt from the collection device.

Features:

1 , Yield, save energy

Device using multi-layer structure, significantly improve the utilization of the heat and save energy; the same time, because the larger bed and the flow of good material to make dried yield, drying quality are increased.

2 , Device control, is the drying process urgent set

Feed speed, vibration frequency can be adjusted, the material in the bed of the drying time can be controlled. Automatic temperature control system can precisely control the drying temperature, drying process to stabilize.

3 , The damage is very small particles, the dry materials to ensure the quality of

Vibration amplitude can be adjusted for equipment and materials along with some rolling down the bed slope, the degree of friction between the particles smaller, have less damage.

4 , Easy to clean

Each floor are equipped with cleaning the mouth with water within the device can operate more convenient.

5 , Equipment, small footprint, can reduce plant investment, while investment in equipment is relatively low.

Application:

New multi-layer vibration dryer can be used in fine chemical, pharmaceutical, food processing, feed and other industries in granular, spherical, strip, dry crystalline materials, such as traditional Chinese medicine pills, the pharmaceutical particles, salt, monosodium glutamate, plastic particles.