Overview:

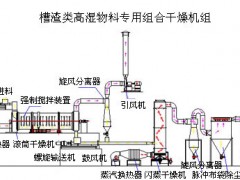

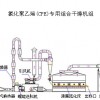

Dregs type of material has a viscosity greater, the higher water features, but also a larger production requirements, a single piece of equipment is difficult to meet the requirements. I have, through continuous research, design dregs class dedicated production line drying. Device used with a blending drum dryer and flash dryer combination, to significantly increase drying efficiency.

Work, hot air in the fan-driven flow from the front roller; wet material through the feeder in a row to join the drum. In the drum, the material with the constant banging drum rotation. Meanwhile, the drum within the special mixing device shattered the material quickly, increasing the effective drying area, so that full access to the materials and air, the material in the water is quickly evaporated. Dried materials have become more loose material from the discharge port. Another part of the powder with air emission, collected through the separation device and a discharged material and exit convergence and the role of the feeding machine into the flash drying machine. In the flash dryer, the material was again crushed and heat exchange with the hot air, to a certain extent and fineness of dried product was blowing grade device, the material in this process is fully dry, to ensure the quality of the material, dry the material after powder for the uniform, without the need for grinding, to achieve greater continuity of production output.

Features:

1 Solve the sticky issue of drying difficult

As the material in a relatively viscous state within the drum dryer drying, and drying machine equipped with special mixing broken equipment, materials, under the rotating drum attached to the tube wall is difficult, so that drying can be carried out smoothly. After drum drying viscous material reduction in the flash dryer for drying in the drying effect is excellent.

2 , Finished as the powder, not need to smash

During the drying process material through the drum dryer mixer broken and flash dryer again smash smash devices and materials have been fully dispersed, at the same time, flash dryer with classifier, effective control of the finished tablets degrees, so that the material was dried powder.

3 , Control stability, high degree of automation

Feed system with variable speed, speed, uniform and stable. Automatic temperature control, drying temperature range of plus or minus a small, drying stability, and improve the drying quality.

Application:

Can be used for residue, rosacea, potato has a higher viscosity of slag and other materials dry.