Overview:

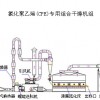

Wood powder dry and has a large output, but not too high drying temperature characteristics, the drying temperature is too high fire is easy, using conventional equipment difficult to meet the requirements of large-scale production. I designed a special drying wood flour production line, using two combined pulse flow drying, achieved good results.

Dry, wet wood powder through the feeder into the first stage pulse continuous flow dryer at the bottom of the drying tube. In a dry tube, wood powder was high-speed hot air to break up to move, materials and air access to the full, water is quickly evaporated. Wood flour by drying after a cyclone collection tube, and then enter the second stage pulse air dryers, drying again, effectively extends the drying time of materials.

Features:

1 Large output

Wood powder in the highly fragmented state of drying, drying speed, short residence time, large capacity.

2 High degree of automation, energy efficient

Using self-feeding system, feed rate and variable speed; drying temperature control, operation Flour at different stages according to the humidity control temperature of each case separately, so that thermal efficiency is increased, while Ensure the quality of the material dry.

3 , Received powder rate

Pulse bag filter with cyclone separator and the combination of powder collection rate of up to 99.5% .

4 , Continuous drying, Simple

Wood flour from a dry and lose access to two feeding device without additional drying, the drying process more smoothly and achieve continuous drying, easy to operate.

User: Guangdong Petrochemical, Maoming petrochemical dozen