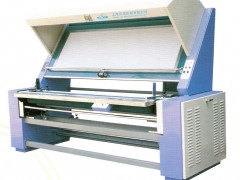

Automatic Inspection Machine

Use

Test all kinds of cloth (needle, shuttle, flat-woven) of the advantages and disadvantages.

Place the fabric will heap test and roll into a bundle.

Fabric inspection and loose bales placed to be stretching the fabric to restore Restore.

Advantage

The machine is equipped with unique distribution system that allows fabric folds into a flat, and roll neatly folded.

Hydraulic pressure on the edge tracking electronic monitoring system that can guarantee the maximum fabric selvage after rolling the same neat, packing more beautiful, easier to use.

Variable frequency speed control motor is reversed to test fabric speed is about 0-70 yards.

With record imports of codec, and different fabrics (knitted, woven cloth) and with two different installation methods, more accurate test measurement of fabric yardage.

Designed for different hard and soft fabric and paper cloth device so that the fabric without tension or write code under test.

Unique design of the release cloth bar, wearing cloth device which can meet the needs of different types of fabrics.

Fabric inspection width 1830MM (standard equipment).

150 for the band-edge devices, 150A for the non-edge devices on the machine (be customized), another company under the customized needs of different customers with different specifications of the machine (after the break before the test, is vindicated volumes are experience anti-roll, different sizes, etc.

Model ; ; YBQ-240 ; ; YBQ-240

Power Supply 1 or 3 Phase ; ; 1 or 3 Phase

Maximum working width ; ; 2450mm ; ; 1830mm

Cloth speed inspection ; ; 0 ~ 64m/min ; ; 0 ~ 64m/min

Accuracy 5 / 1000 5 / 1000

Power ; ; 1.5KW 1.5KW

Net / gross weight ; ; 500/560kg ; ; 450/510kg

Dimensions ; ; 2600 * 2100 * 2100mm ; 2600 * 2100 * 2100mm