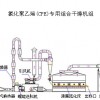

Energy efficient mushroom, straw mushroom special belt drying machine, drying equipment - uniform drying is a box-type structure, with multi-box belt, belt loop movement in the box, the material from the hopper into the box, absorbed through the delivery device plate, uniform distribution of materials in the first layer of the conveyor belt, through the chain of transmission, overturned by the chain into the material, lower, lower back has been the turn-by-turn to the last layer of discharge. Air through the heat exchanger resulting from the bottom of dry air from the fan blowing up layer attack and counter-current contact with materials to conduct heat and mass transfer, so as to achieve the purpose of removing water.

Can set the appropriate operating conditions, according to the corresponding ventilation dry state, can be freely adjust the temperature, air flow and other operating conditions.

Free adjustment processed water, as free to adjust the material drying device stop traffic, stay. Therefore free to set the water content of the processed products.

Little damage shape and material from the drying device, a stationary mobile, can hardly destroy the shape of the product, even a small amount of dust flying objects can be set by the weak wind in the pipe or bag filter for collection.

Can use a variety of conveyors, dry material according to different kinds of metal wire belts addition, the vibration plate can also be used.

Belt can be cleaned, separate heating room and drying room, easier to clean transmission belt.

On request, can be assembled in the equipment floor cleaning device, a small amount of material out on the floor on scraping material sent to the client.

Under the production of materials with different moisture can choose multiple devices in series in order to increase production. It applies to potato, carrot, onion, eggplant slices tempeh, onion, tomato, mushroom, candied fruit, chestnuts, tea and other agricultural products, as well as Chinese herbal medicines such as sheet, strip, granular materials such as drying. Materials for the slow loss of water is especially suitable material. My company has cash, new and old customers with a material testing machine.

Can set the appropriate operating conditions, according to the corresponding ventilation dry state, can be freely adjust the temperature, air flow and other operating conditions.

Free adjustment processed water, as free to adjust the material drying device stop traffic, stay. Therefore free to set the water content of the processed products.

Little damage shape and material from the drying device, a stationary mobile, can hardly destroy the shape of the product, even a small amount of dust flying objects can be set by the weak wind in the pipe or bag filter for collection.

Can use a variety of conveyors, dry material according to different kinds of metal wire belts addition, the vibration plate can also be used.

Belt can be cleaned, separate heating room and drying room, easier to clean transmission belt.

On request, can be assembled in the equipment floor cleaning device, a small amount of material out on the floor on scraping material sent to the client.

Under the production of materials with different moisture can choose multiple devices in series in order to increase production. It applies to potato, carrot, onion, eggplant slices tempeh, onion, tomato, mushroom, candied fruit, chestnuts, tea and other agricultural products, as well as Chinese herbal medicines such as sheet, strip, granular materials such as drying. Materials for the slow loss of water is especially suitable material. My company has cash, new and old customers with a material testing machine.