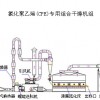

Air dryer hot air into the dryer and after the rapid impact of materials and materials in an instant mixing of fluidization of materials to maximize the contact area with the air to rapidly evaporate the water, gas-solid separation obtained after removal products. Pulse flow drying air dryer in the straight pipe based on the increase in coarse buffer management aims to increase the gas-solid relative movement so as to enhance the drying rate. apply sticky sticky little or no dry cake loaded materials are generally required before drying mechanical dehydration. air dryer drying time is generally shorter 1-4 seconds, the product temperature has not increased from the dryer before, so suitable for drying heat sensitive materials.

dry water-based forms to surface water, water containing more material inside is more difficult to process requirements. The machine can be designed according to process requirements blast system, induced draft system, and induced air system, fan can double as distributor. Fan blowers can be used in the inverter continuously variable transmission system, achieving system "0 pressure " precise control in cyclone feed Department or Department of easy leakage. welded pipe for general easily inflammable and explosive materials, product materials and the temperature is too high, the factory has unique technology to dry and pipe inner wall, flange and other materials through the Department ensure that materials are not absolutely smooth, stay inside.

drying strength, equipment investment Province: air drying equipment capacity is the largest water evaporation capacity from 50kg/h-1500kg/h, while the volume of small equipment investment, and other drying equipment can not match.

high degree of automation, product quality: air drying materials were all in the pipeline, drying time is short (only O.5-2 seconds) can be automated, therefore, the product is not with the outside world, less pollution, good quality.

air dryer for drying strength air flow rate as high, particles well dispersed in the gas phase, all particle surface area can be effective area as dry, so dry and greatly increase the effective area. Meanwhile, due to the dispersion and stir drying effect, so that the surface gasification constantly updated, so the dry heat and mass transfer process in the recorder. Drying time is short gas-solid contact time is very short drying time, generally 0.5 ~ 2 seconds, up to 5 seconds. Materials, thermal denaturation is generally a function of temperature and time, therefore, for heat-sensitive materials will not cause overheating or low melting point or decomposition affecting its quality.

air dryer thermal efficiency and air drying by gas-solid flow operation, and, on the surface gasification stage, the material is always connected solution with the wet bulb temperature of the gas, not more than 60 ~ 65

Total: 0 [Show All] Related Reviews