Skype: gjmyxjj

email: info7526(at)guangxing-screens(doc)com

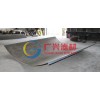

The continuous slot well screen is widely used in the world for water ,oil and gas wells,and the dominant screen type is used in the water well industry.Continuous slot well screen is made by winding cold rolled wire,approximately triangular in cross section,around a circular array of the longitudinal rods.The wire is attached to the rods by welding,producing rigid one piece units having high strength characteristics at minimum weights.

Slot size (mm): 0.10, 0.15, 0.2, 0.25, 0.30-6mm

Open area: up to 37%

Material: low carbon steel, low carbon galvanized steel (LCG) steel treated with plastic spraying, stainless steel (304,316L ect)

Lengths up to 6 meters

Diameter: 1.5", 2", 3", 4", 6", 8", 10", 12", 14",16",18"

End connection: plain beveled ends for butt welding or threaded.

Performances:

1.Production process continuity : V shaped profile wires creating slots which enlarge inwardly and therefore avoid clogging and minimize downtime.

2.Low maintenance costs:Separation at the screens surface which can easily cleaned by scraping or back washing.

3.Maximum process output:Precise and continuous slot openings resulting in accurate separation without loss off media.

4.Low operational costs:Large open area with an effective flow .high yield and a low pressure drop

5.Long live:welded at each intersection creating a strong and durable screen

6.Reduced installation costs:Supporting constructions eliminating costly support media and enabling a maximum flexibility in the design of components

7.Chemical and thermal resistant:A variety of corrosion resistant stainless steel materials and many ecotic alloys suitable for high temperatures and pressures.