1. Constitution Structure:

Top Coating PVDF/Nano-PVDF (KYNAR 500)

Aluminum skin

Macromolecular lamination film

Nontoxic polyethylene core or No-combustible filled core

Macromolecular lamination film

Aluminum skin

Service coating or mill finished

2. Characteristic:

Fire safety: The outer aluminum sheets and the inner fire-resist polyethylene function the panel having an excellent fireproof performance, and meeting the standard_smoke less and no harmful gas.

Weather-resistance: Superior weather-resistance and ultraviolet (UV) resistance, acid-resistance and alkali-resistance, suitable for all natural environments.

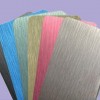

Smooth Surface: The fire-resist ACP provide superior and smooth surface, coated with the PVDF inheriting the excellent surface characteristics, satisfying the modern building with perfect appearance.

High Strength: The fire-resist ACP use high quality aluminum with the high quality fire-resist polyethylene core which can be greatly enhanced strength, ensure the performance of wind-pressure resistance, shockproof, and anti-impact.

Easy Processing: ACP is easy to cut, slot, punch, bend into circular, rectangular and other shapes also can be designed to various modeling according to your ideas.

Exertion Design: The fire-resist ACP has series of glossy and shape to meet the designer great originality, achieve perfect results.

3. Specification

Thickness: 2mm, 3mm, 4mm, 5mm, 6mm

Alu thickenss: 0.06-0.50mm

Width: 900 ≤ W ≤ 1600

Length: Customized

| Application: | Interior Decoration, Exterior Wall Cladding and Sign | |

| Dimensional Tolerances | Thickness(mm) | ±0.2 |

| Width(mm) | ±2 | |

| Length(mm) | ±3 | |

| Diagonal(mm) | ±5 | |

| Thermal Expansion | 2.4mm/m at 100 ºC temp difference | |

| Aluminum Thickness(mm) | ±0.02 | |

| Surface Properties | Pencil Hardness | >HB/>2H |

| Temperature Resistance | -50 ºC to +80 ºC | |

| Impact strength (kg. cm) | 50 | |

| Boiling Resistance | Boiling for 2 hours without change | |

| Acid Resistance | Immerse Surface in 2% HC1 for 48 hours without change | |

| Alkali Resistance | Immerse Surface in 2% NAOH for 48 hours without change | |

| Oil Resistance | Immerse Surface in 20# engine oil for 48 hours without change | |

| Solvent Resistance | Cleaned 100 times with dimethylbezene without change | |

| Cleaning Resistance | Over 1000 times without change | |

| Peel Strength 180 ºC | 180oC>5 newton/mm | |

| Product Properties | Sound Absorption NRC | 0.05 |

| Sound Attenuation RW db | 23/24/25 | |

| Water Absorption % by volume | 0.0047/0.0057/0.0012 | |

| Core Composition | LDPE Polyethylene, Non- Combustible Material | |