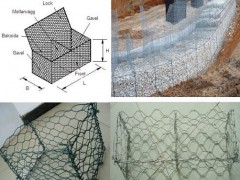

Long billion wire cage

cage wire mesh, galvanized wire mesh covered plastic lead, flood control wire cage, flood control and lead screen, ecological mesh, gabion wire mesh factory price size

Long billion wire gabion cage is also called metal wire woven by the angular Network (Hexagonal) cage made of: (1) No galvanized hexagonal wire is the use of large high quality low carbon steel wire weaving, wire diameter of 2.0mm-4.0mm, steel surface usually protected by hot dip galvanizing, galvanized protective layer thickness, according to the requirements of the system to do, galvanized the largest up to 300g/m2.

(2) galvanized wire, plastic coated galvanized wire hexagonal wire mesh is coated with a layer of PVC protective layer, and then woven into a variety of hexagonal. This layer of PVC protective coating will greatly increase the protection of highly contaminated environment and through the choice of different colors, so that it can, and the integration of the surrounding natural environment. Aaaaa

all of the following tests must be used in woven wire mesh cage before:

(1) All steel (including the manufacture of wire mesh cage, tied ligation wire) the tensile strength of not less than 515MPa.

(2) Elongation: Test samples of at least 30cm long, elongation not less than 12%.

(3) galvanized steel wire size error is less than 0.05 mm.

(4) zinc coating attached to the request: When the galvanized steel wire around 4 times the diameter of the rod 6 weeks, rubbing with your fingers, the zinc coating does not peel off, fracture phenomenon.

outsourcing resin film (PVC): (1) tensile strength of not less than 2016MPa. (2) not less than 200% elongation.

wire mesh cage: (1) tensile strength of not less than 4213kN / m. (2) Anti-punching strength of not less than 2316kN / m. (3) edge wire connection strength is not less than 1715kN / m.

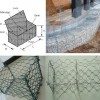

wire cage assembly:

(1) wire cage unit is shipped complete to the project site. First of all construction workers will erect the piece to ensure that all pieces in the correct position.

(2) lashing wire cage of the four corners of points, lashing can be used to tie ligation wire or metal buckle.

(3) tie ligation wire or metal buckle with septa and network itself will be connected,

the ecological advantages of wire cage

:

is the use of heavy hexagonal wire cage assembly into cages like, within the project site to the cages filled with certain specifications, to meet certain requirements of the stone, to form self-permeable, flexible, ecological protection structure.